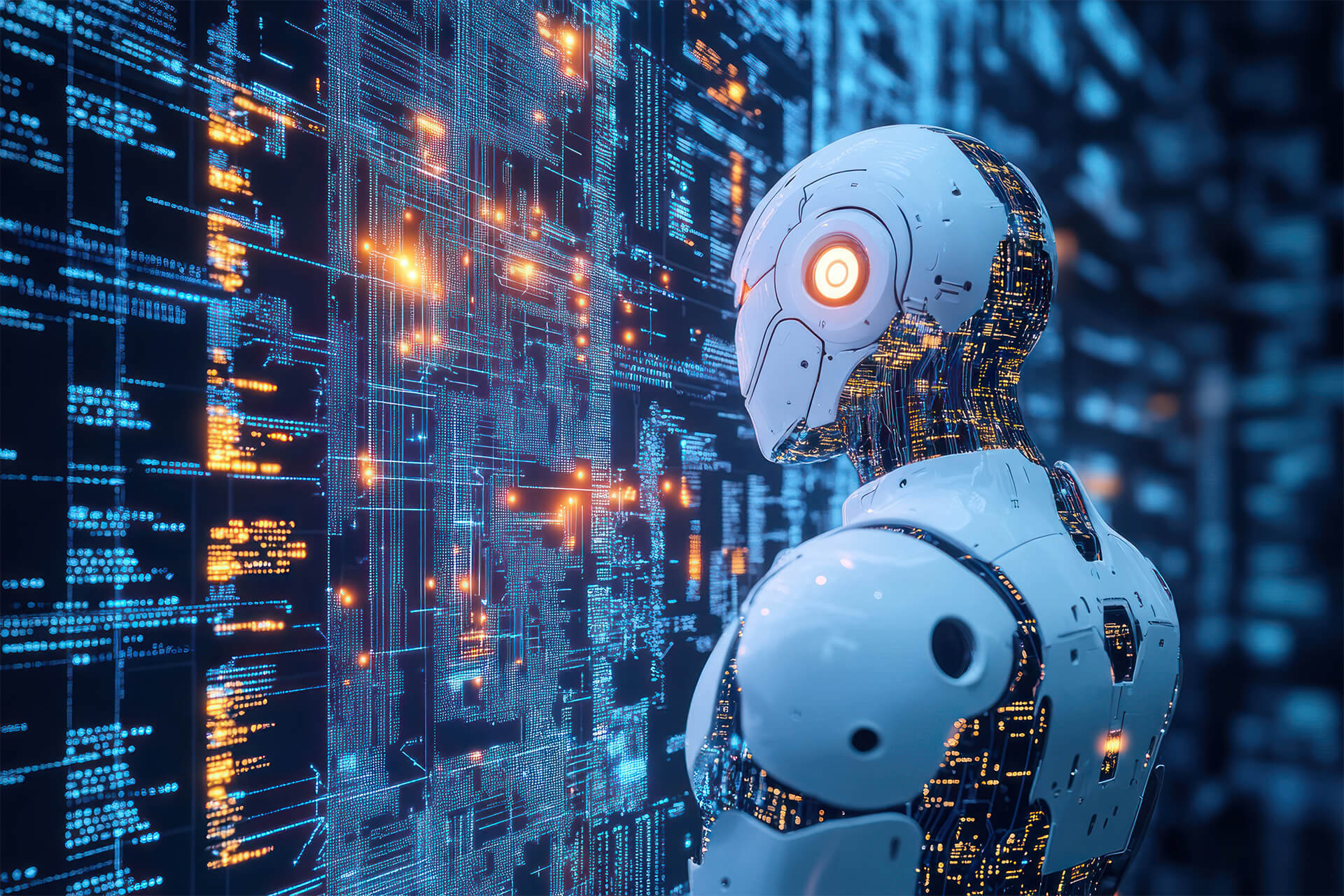

Industry 4.0 with Value – Technologies Aligned with Your Goals

Many of our clients ask themselves whether a given solution can be implemented in their organization and whether it will bring added value. Often, a challenge lies in developing a roadmap – how to prepare for a given investment or change that involves entering the previously unknown territory of Industry 4.0.

We believe that IT environments, modern technologies, and Artificial Intelligence can significantly support organizations in achieving their business goals.

These goals often include accelerating work, solving problems, or optimizing costs. For over 20 years, we’ve helped companies meet such challenges in a traditional way as well – by working with people and building optimal work standards, without always relying on an entire suite of modern technologies. This practical and balanced approach sets us apart from other providers of Industry 4.0 solutions.

Behind every tool we propose is more than just complex algorithms and precise devices - those are provided by all reputable technology vendors.

At LUQAM, every solution is the result of collaboration between experts in production and business management, who work hand-in-hand with the client to implement it.

Our experience in leading transformation projects across most industries, with companies of different sizes and working models, gives us a strong mandate to help integrate selected Industry 4.0 technologies into production systems – in a pragmatic way that delivers more than a sense of modernity: it delivers true added value.

How we help:

Artificial Intelligence (AI)

- Decision support

- Predicting future events and trends

- Preventive actions – e.g., in maintenance or quality assurance

Robotics and Automation

- ROI calculation

- Optimal integration of new devices/lines into layout and flow

- Independent consulting and evaluation of specific solutions

Digital Twin

- Simulation of reduced Technical Cost of Production

- Optimal layout and flow planning

- Hypothesis testing in a digital environment

Internet of Things (IoT)

- Measurement of key quality-related factors

- Effective data collection

- Improved predictive analytics (e.g., for failure forecasting and service needs)

contact form

Learn more -

get in touch with us!

Łukasz Ekiert

newsletter