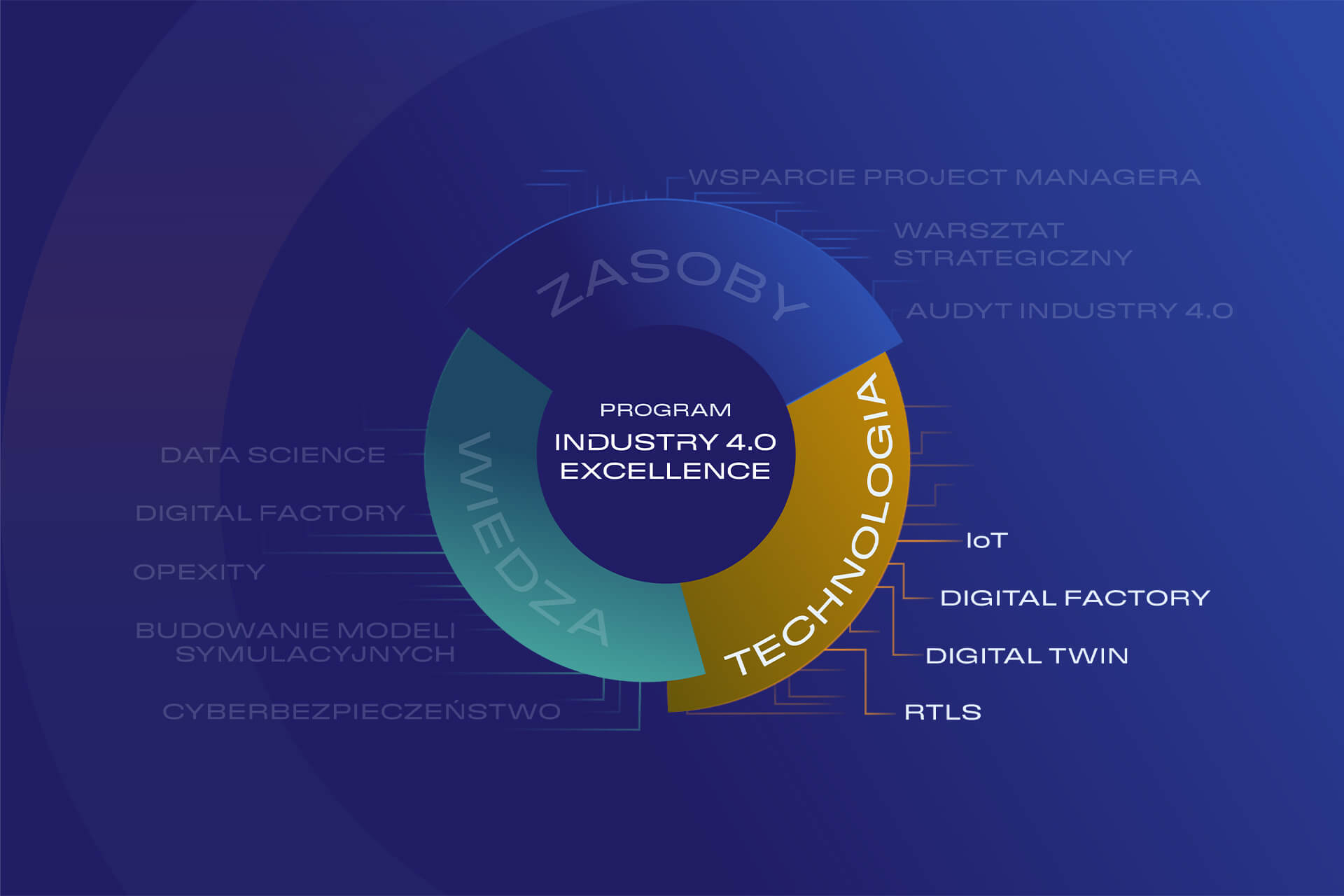

Industry 4.0 Excellence Subscription Program

Industry 4.0 Excellence is a comprehensive subscription program designed specifically for manufacturing companies aiming to unlock the full potential of digitization, the Internet of Things (IoT), and modern technologies.

This program offers more than just access to knowledge and resources – subscribers receive complimentary access to Industry 4.0 technologies worth up to PLN 500,000 annually, including: Digital Twin, IoT, Digital Factory, MES, RTLS, Opexity.

All of this is available under a single, transparent monthly fee.

Don’t wait - get ahead of the competition today!

Why choose Industry 4.0 Excellence?

Our solutions combine expertise, cutting-edge technology, and a personalized approach.

The program not only supports companies in digital transformation but also delivers:

- increased operational efficiency,

- cost reduction through process optimization,

- modern tools for management and analysis,

- future-proofing your business for upcoming challenges.

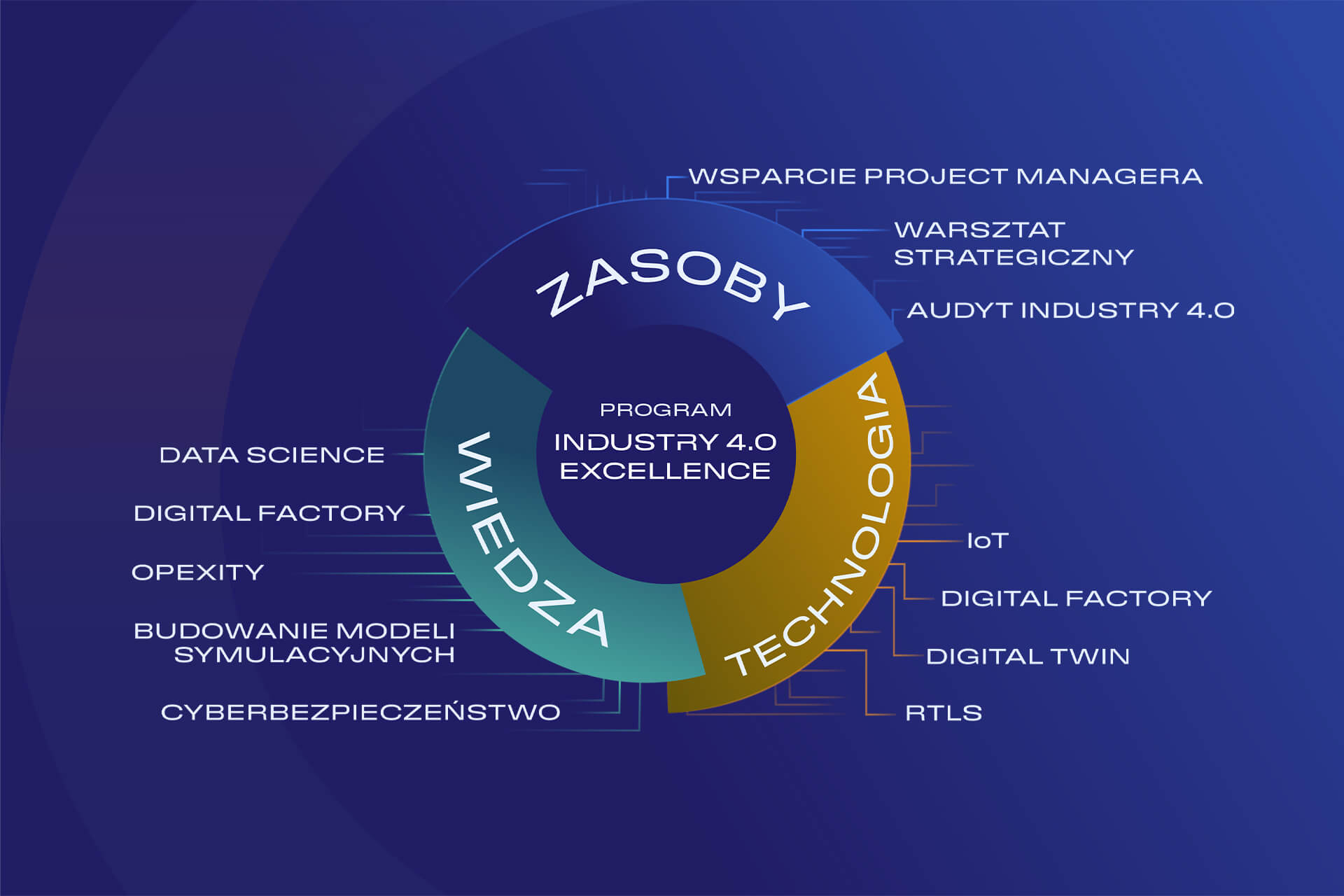

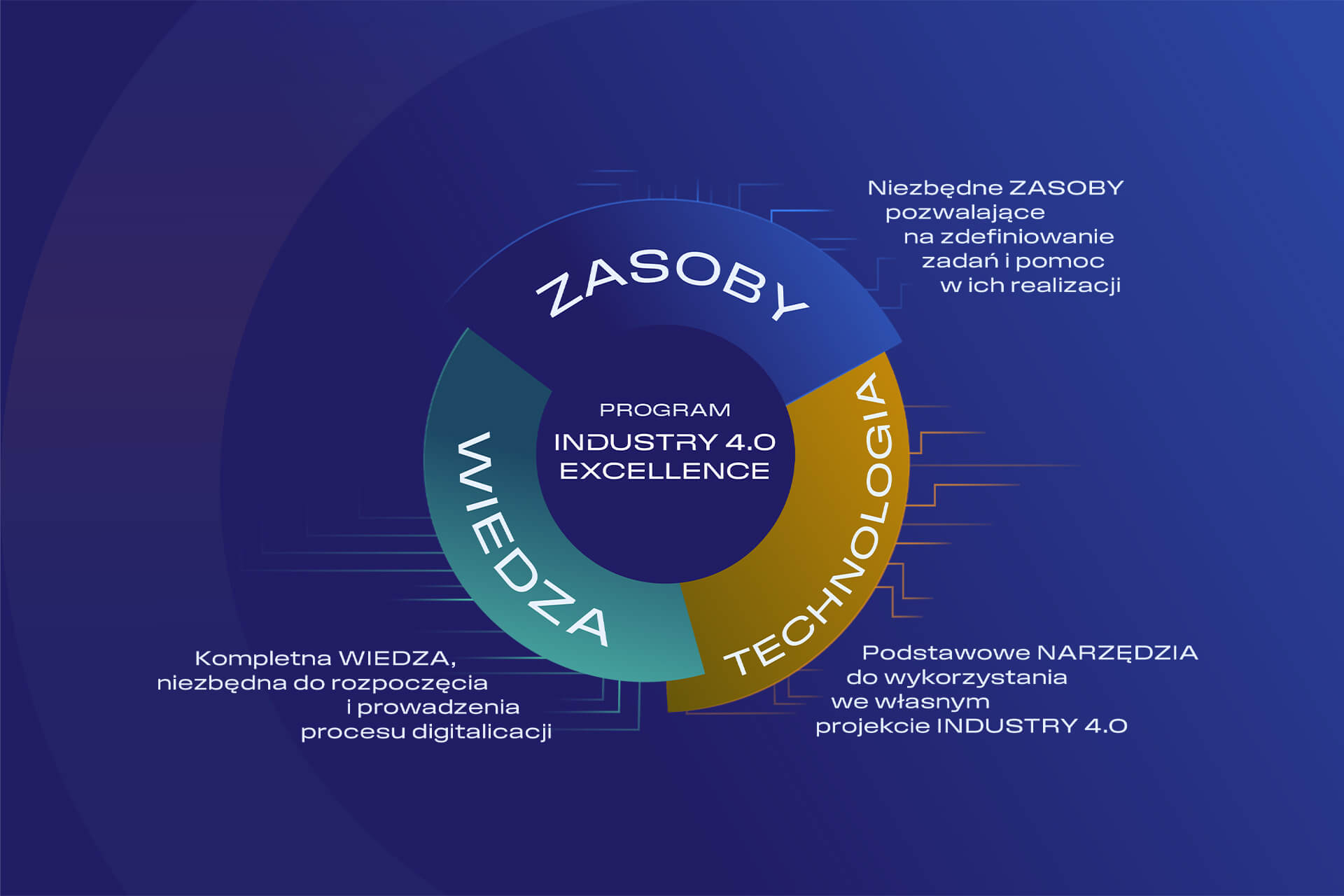

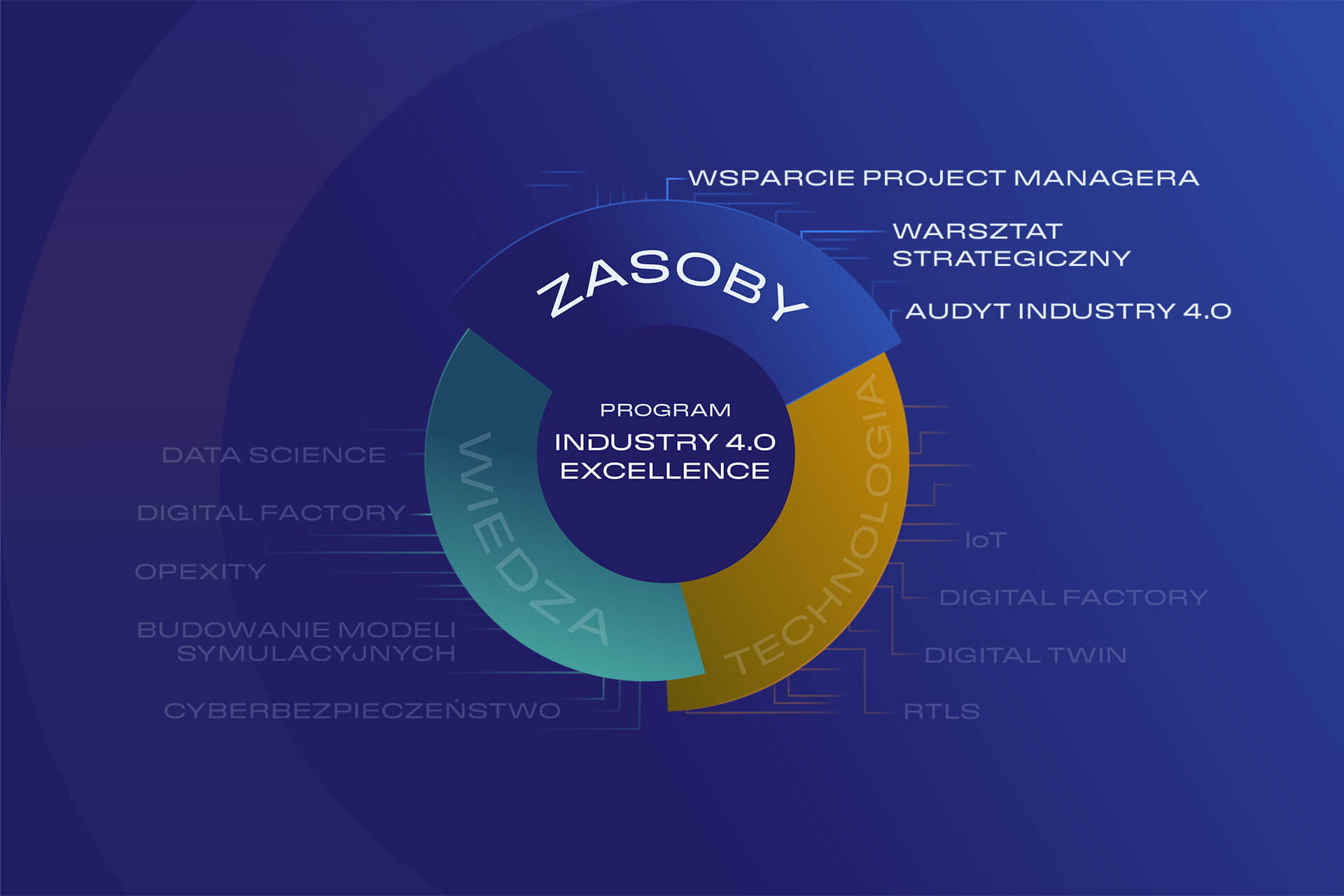

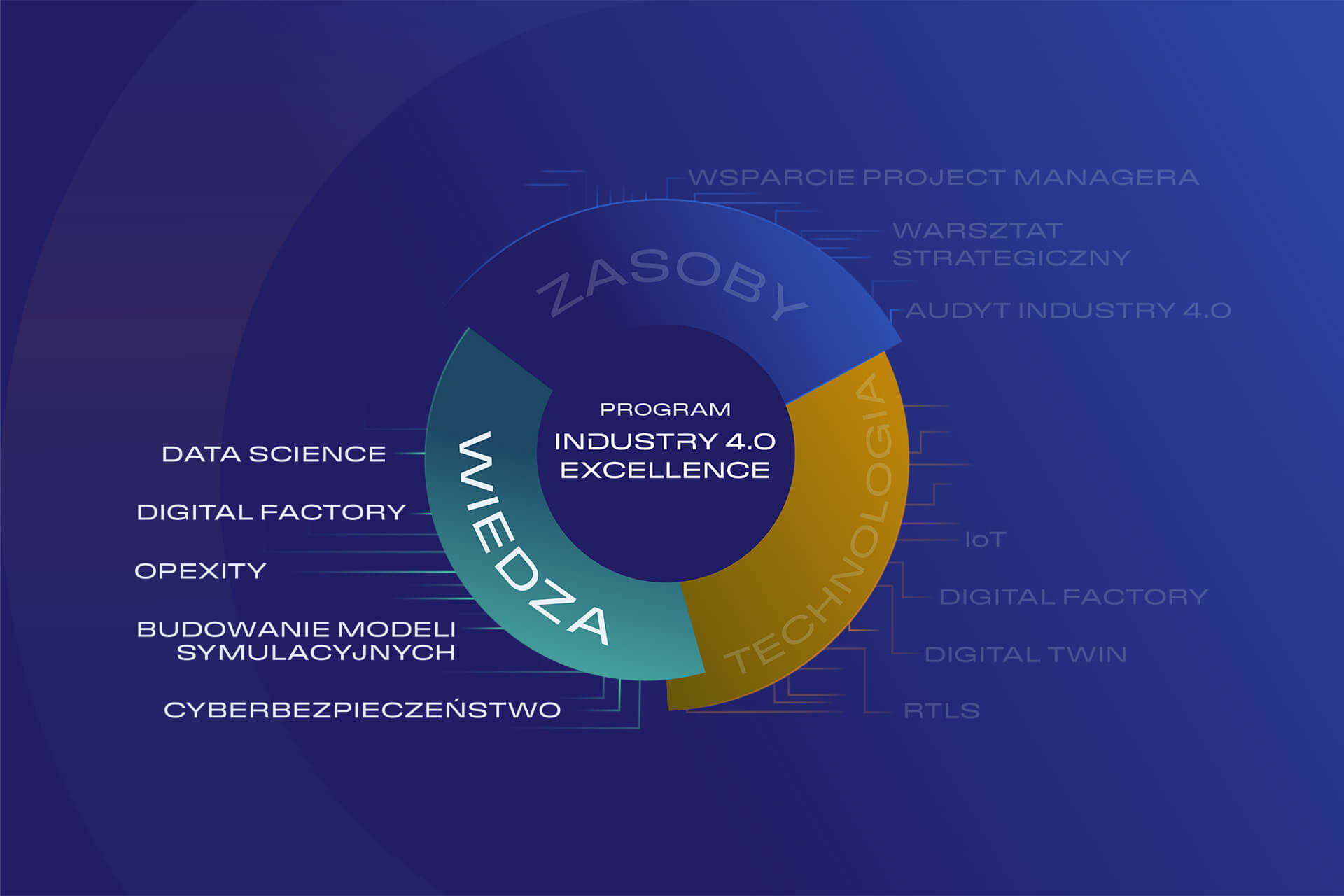

Resources - the key to scalability and optimization

To implement Industry 4.0 effectively, an organization needs the right resources – both human and material.

Our program delivers a balanced mix of professional resources to successfully execute your Industry 4.0 strategy.

Knowledge - the foundation of a conscious transformation

Industry 4.0 is not just about technology – it’s about the ability to use it effectively.

A successful transformation depends on the awareness of both management and staff in modern production methods, data management, and predictive analytics.

Do you have questions?

Technology - the heart of modern manufacturing

While modern technology is the foundation of Industry 4.0, its full potential can only be realized through the right approach to knowledge and resources.

- IoT, smart sensors, and Digital Twin – provide process visibility and enable real-time optimization.

- Artificial Intelligence and Big Data analytics – support data-driven decision-making.

- Digital Factory – software that digitizes both business and production processes.

LUQAM at AI & INDUSTRY EXPO 2025

Visit our booth – we’ll be happy to present partnership opportunities tailored to your company’s needs.

The Industry 4.0 Excellence Program is a real response to the challenges of modern manufacturing – and that’s exactly what we’ll be showcasing at AI & INDUSTRY EXPO 2025.

What’s included in the Excellence Program?

How is the program implemented?

Let us help your company achieve operational advantage!

Benefits of the Industry 4.0 Excellence Program

Competitive advantage

Implementing the latest IoT, AI, and digital solutions gives your company a significant edge in a rapidly evolving market.

End-to-end expert support

Strategic workshops, custom strategy development, and on-site PM visits ensure professional assistance throughout the transformation.

Cost and process optimization

Eliminate bottlenecks, reduce downtime, and manage resources more efficiently – cutting operational costs significantly.

Team upskilling

With training in digitization, AI, and cybersecurity, your employees become a highly qualified team ready to embrace the future.

Data-driven decision-making

Leverage Digital Twin technology and real-time analytics to make fast, accurate, and safe business decisions.

Real-time monitoring

Track machine performance and resource location with RTLS and TiMES for enhanced operational control.

Access to premium technologies

Enjoy access to Industry 4.0 technologies worth up to 500,000 PLN annually – with no additional charges.

Future readiness

Take your company to the next level of digitization, ensuring sustainable growth and resilience in the face of market challenges.

contact form

Have questions?

We’re here to help - contact us today!

Daniel Taborski

newsletter

01

01