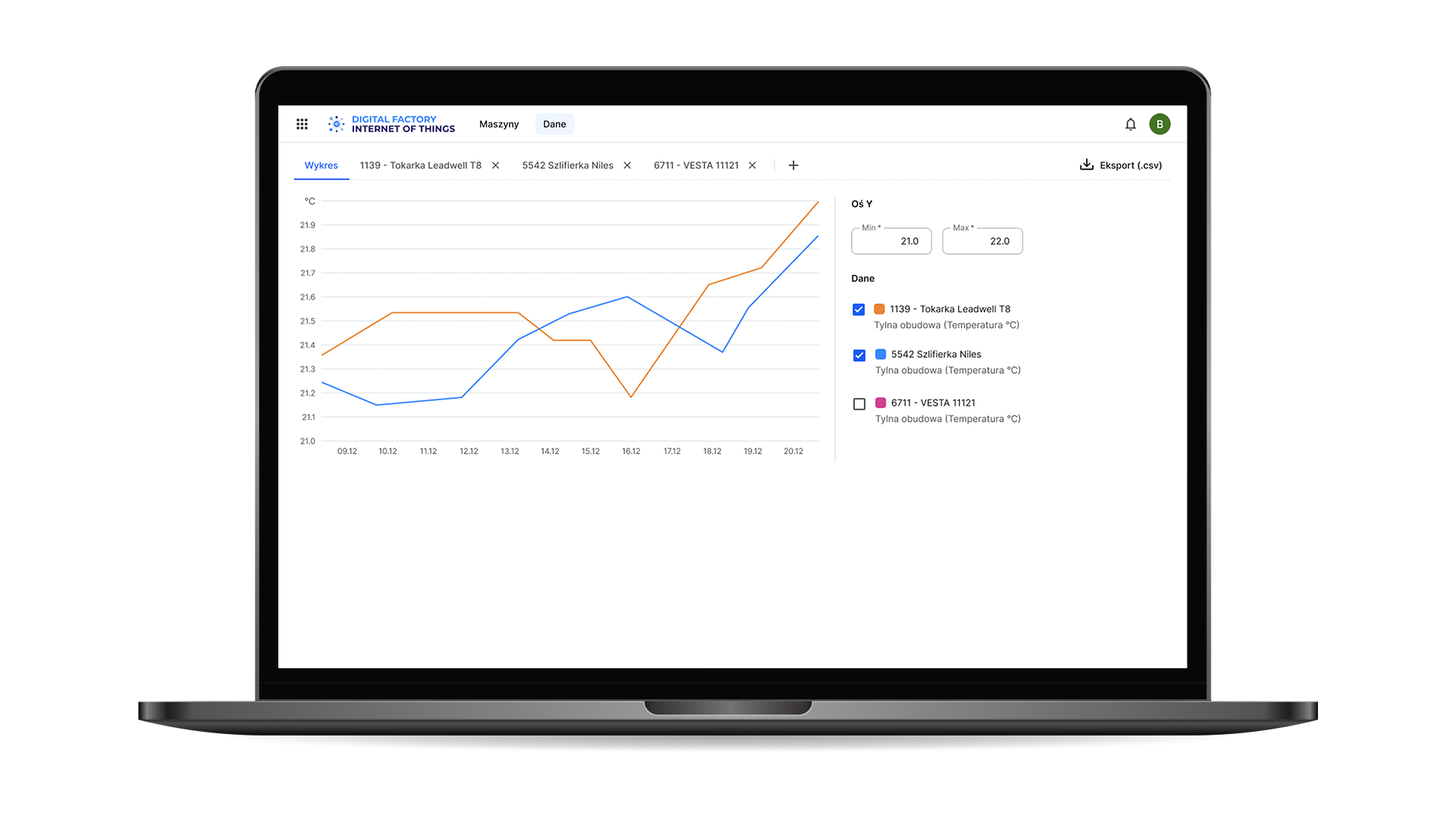

Temperature Trend Chart

Track machine casing temperature changes in real time.

The interactive chart, based on live IoT sensor data, enables accurate diagnostics and supports maintenance teams in preventing breakdowns.

We’re Showcasing Our IoT Solution at AI & INDUSTRY EXPO

Visit our booth at AI & INDUSTRY EXPO to see our IoT sensors and LUQAM’s digital applications in action!

Explore the Subscription-Based IoT System

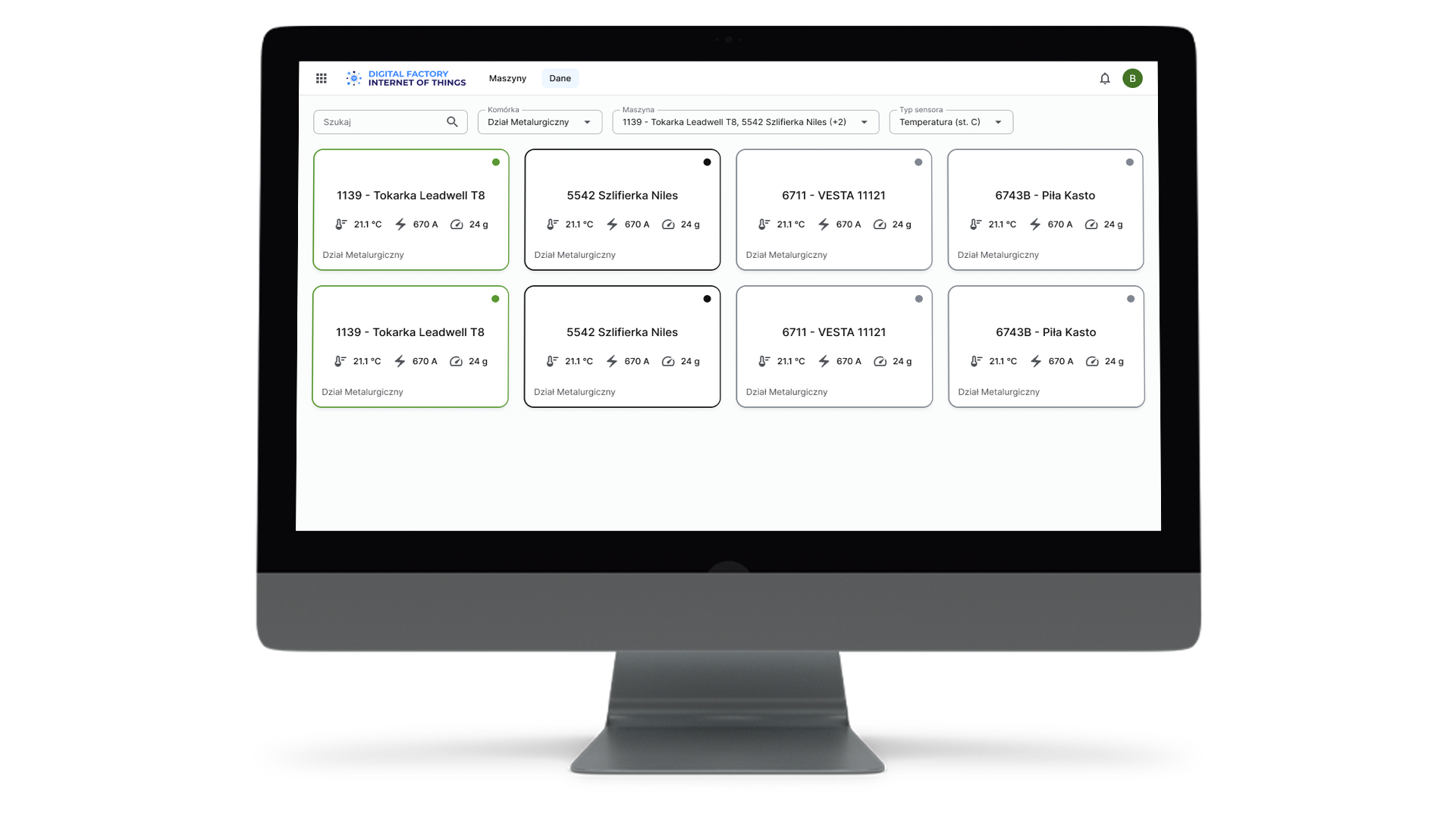

Machine Overview Panel

Get instant visibility into your machine park.

Our clear and easy-to-read dashboard displays data from IoT sensors – including temperature, current draw, and energy use – allowing you to quickly assess machine health in any production zone.

Special Offer: 10 Free Sensors for 3 Months for the First 10 Companies

See Inside Your Machines – It’s Easier Than You Think

With LUQAM, collecting machine data is not only simple – it’s highly cost-effective.

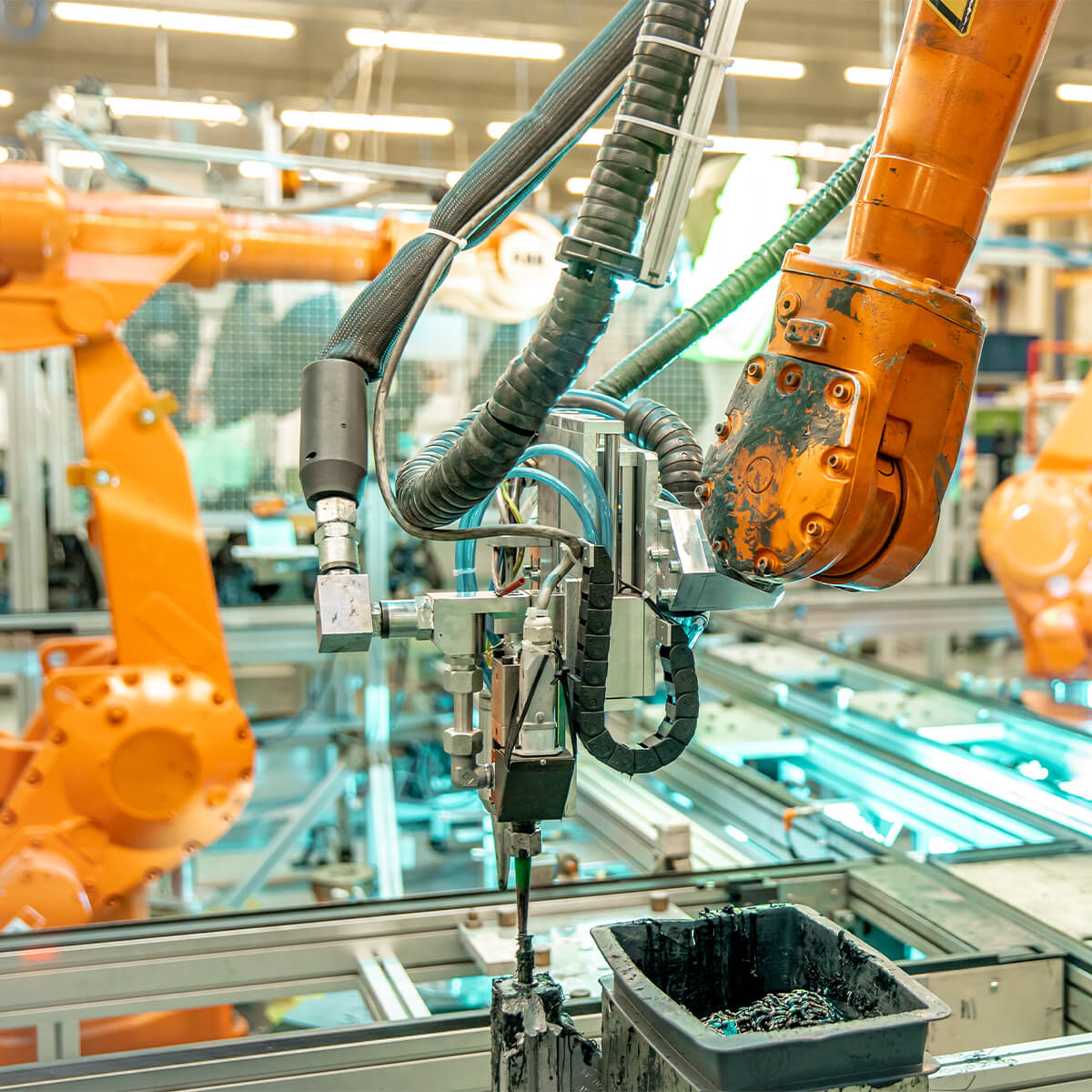

Live view of machine operation

Early detection of anomalies

Smart path to Industry 4.0 powered by AI

LUQAM’s IoT System – Smart Production Monitoring

Our IoT platform is built for manufacturers aiming to improve operational efficiency, gain full control over production assets, and embrace the Industry 4.0 paradigm.

By integrating purpose-built sensors with a user-friendly application, the system enables real-time equipment monitoring. Instant access to machine data allows for quick reactions and reduced downtime.

This flexible solution is suitable for companies of any size or sector. The collected data forms a strong foundation for advanced analytics and AI-driven process optimization.

With LUQAM, you get more than just technology – you gain expert support in data analysis, process improvement, and digital transformation.

Types of Sensors in the LUQAM IoT System

How IoT System Deployment Works

Start your digital transformation today – book a free consultation and explore the possibilities.

Why Choose LUQAM’s IoT System?

LUQAM’s IoT system offers more than just real-time machine and process monitoring.

It’s a powerful tool designed to truly drive the growth of your production operations.

Our IoT solution goes beyond monitoring – it supports your digital transformation journey. By integrating AI and machine learning technologies, it enables not only data collection but also intelligent analysis. Users gain actionable insights that help them make better decisions, minimize downtime risks, and increase operational efficiency.

In practice, this means:

- Predictive maintenance – the system analyzes historical and real-time data to detect anomalies and predict failures before they occur.

- Continuous process optimization – enabling fine-tuning of machine settings for higher productivity.

- Automatic state classification – eliminating the need for manual data interpretation.

What sets us apart is the modular architecture of our system, which can be easily customized to meet the unique requirements of any facility – regardless of industry or scale. With its intuitive interface and access via web browsers or smartphones, deployment and daily use are seamless and user-friendly.

LUQAM also provides end-to-end support – from sensor selection and installation to data analysis and the development of predictive models.

Benefits of Implementing the LUQAM IoT System

Real-time monitoring

Continuously track machine performance with sensors providing live data on ON/OFF status, current levels, temperature, and vibrations. Stay informed 24/7.

Centralized data access

A clear, online dashboard gives you instant visibility into your equipment status from anywhere, on any device.

Trend analysis and predictive maintenance

Detect irregularities before they escalate. Historical and real-time data enable predictive maintenance strategies, reducing unexpected downtime.

Reporting and data exports

Easily export data to Excel. Generate intuitive charts and summaries to make data-driven decisions, not assumptions.

Increased operational efficiency

Respond faster to stoppages and technical issues. Improve OEE and cut costs with actionable insights.

AI and automation ready

Collected data forms the foundation for AI algorithms that optimize processes, improve quality, and support advanced diagnostics.

Minimal IT infrastructure impact

The system works without public IPs, NAT changes, or complex configurations. Fast, secure, and encrypted with AES standards.

Seamless integration with Digital Factory cloud

Access production data anywhere, anytime, through LUQAM’s Digital Factory ecosystem.

contact form

Adopt a Smarter Way to Manage Production - Contact Us Today!

Bartłomiej Rachwał

newsletter