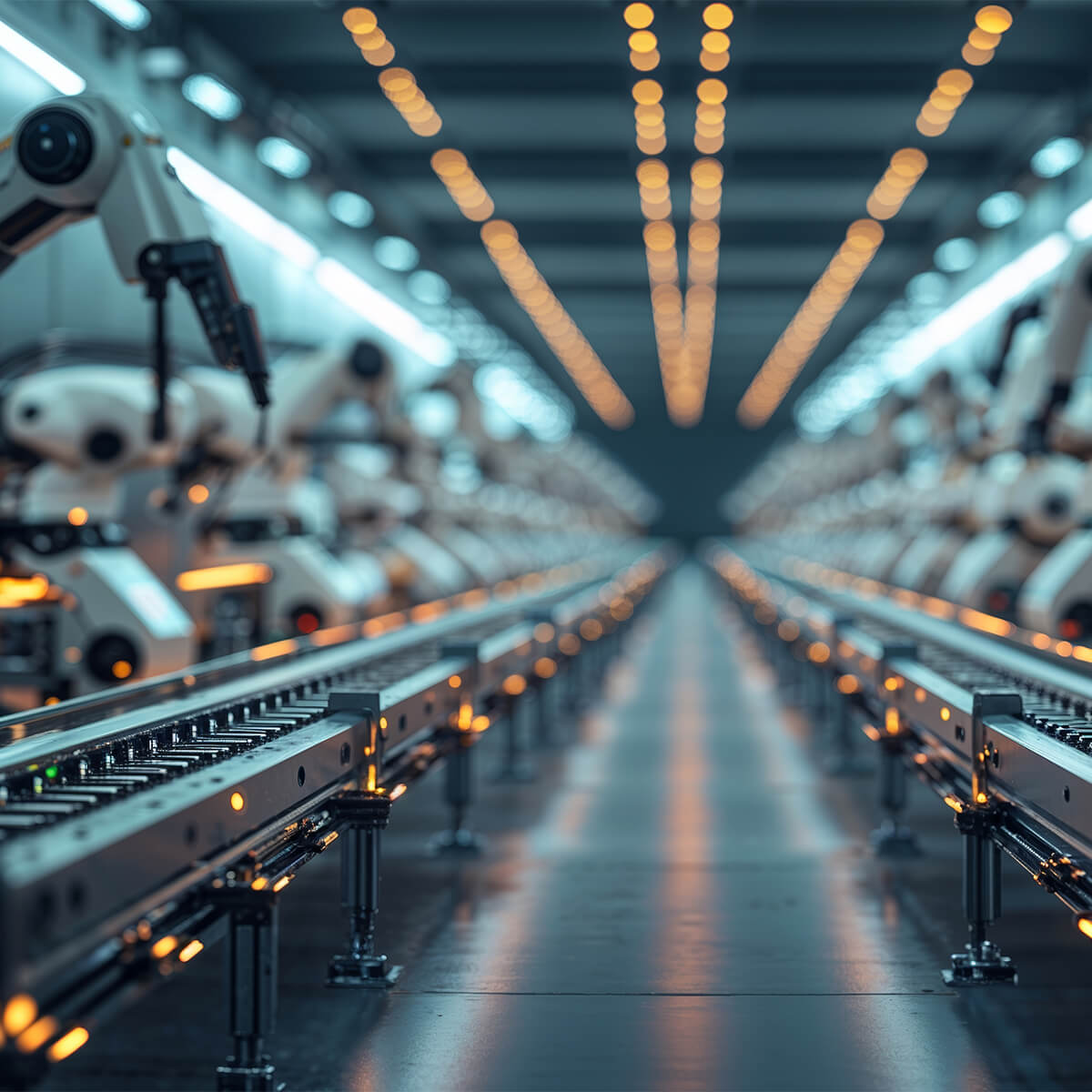

Operational Excellence as a Growth Driver

Staying competitive in today’s market requires constant process improvement and the ability to adapt quickly to changing business environments.

In many cases, optimizing individual areas is no longer enough – a full-scale transformation is needed. This includes refining the organizational structure and implementing cutting-edge digital tools based on Industry 4.0.

Don’t wait – stay ahead of your competitors.

LUQAM Transformation Methodology

We support companies by tailoring transformation strategies to their market position, internal capabilities, and strategic goals.

Our approach is based on data-driven diagnostics, modern tools, and a structured implementation model.

A well-executed operational transformation improves process performance, reduces operating costs, and increases long-term competitiveness.

Operational Transformation

Key Stages

of Collaboration:

Process Analysis and Diagnosis

Solution Design

Implementation and Performance Monitoring

What We Deliver as Part of the Collaboration

Stages of Operational Transformation Implementation

Operational transformation is a process that requires precise planning and tailoring to the individual needs of each organization. Our methodology includes the following key stages:

Our Experience

For many years, LUQAM has been supporting companies in carrying out comprehensive operational transformations tailored to the specific needs of various industries. With extensive experience and proven methodologies, we help organizations streamline their processes, optimize organizational structures, and implement modern technologies aligned with Industry 4.0.

Our approach is based on developing transformation strategies that are tailored to the unique challenges and goals of each organization. This allows us to deliver not only fast and measurable results, but also long-lasting changes that build sustainable competitive advantage.

Contact us – together we will create an operational transformation plan that will increase the efficiency and competitiveness of your business.

Benefits of Operational Transformation

Increased Operational Efficiency

Improve resource use, reduce waste, and streamline workflows.

Higher Product and Service Quality

Achieve consistent standards through process control and KPI-based monitoring.

Business Agility

Adapt quickly to market shifts and client expectations.

Employee Engagement

Involve your team in the transformation process and nurture a performance-oriented culture.

Cost Reduction

Reduce operational and procurement expenses through process redesign.

Process Transparency

Enable better decision-making with real-time performance monitoring tools.

Manufacturing, Logistics & Quality Optimization

Get measurable results across the entire value stream, from production to delivery.

contact form

Let’s start your transformation.

Contact us to create a tailored strategy for your business.

Janusz Dziedzic

newsletter

01

01