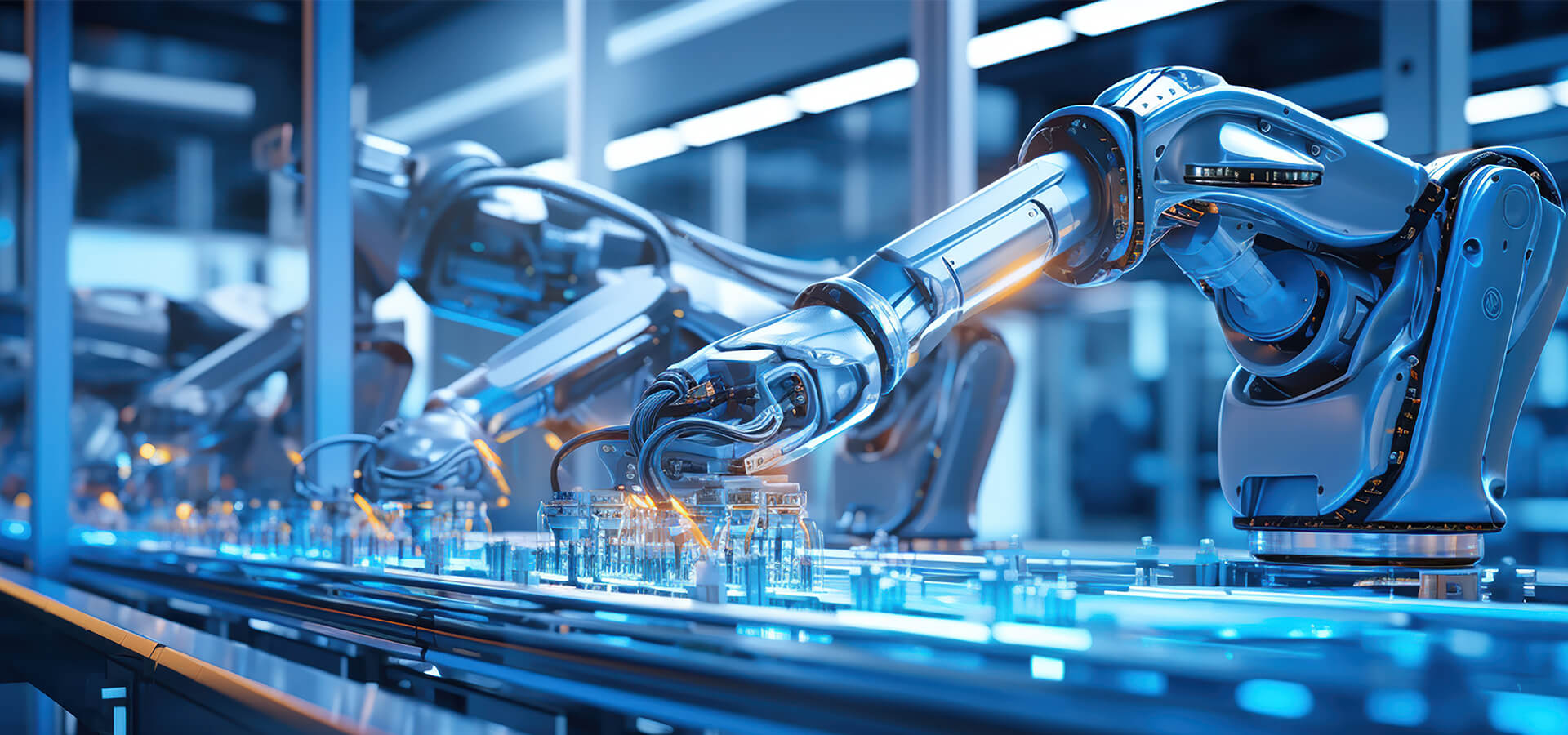

Create a Digital Twin of Your Factory!

Design advanced 3D simulations, analyze data, and optimize processes in real-time.

With Digital Twin technology, you can create a virtual copy of your facility, enabling analysis, optimization, and testing scenarios without interfering with actual production.

Predict failures, test “what if” scenarios, and make optimal decisions with Digital Twin technology!

Free Consultation: Find out if a Digital Twin is the right solution for you.

Digital Twin - Advanced Technology at Your Fingertips

Industry 4.0 Solutions

3D Layout Design

Virtual Reality (VR)

Autonomous Guided Vehicles (AGV)

How Long Does It Take to Create a Digital Twin?

The time required to create a Digital Twin depends on factors such as the project’s scale, the type of system being modeled, the amount of data available, and the technologies required.

Simple Implementations: A few days or weeks. Comprehensive Digital Twins of entire facilities: Several months or more due to the large amount of data required.

Iterative implementation helps spread out costs and align investments with current needs.

Benefits of Digital Twin Technology

Comprehensive Implementation or a Step-by-Step Approach

The process of developing a Digital Twin can be carried out iteratively, gradually building the digital replica based on current needs and available resources.

What Is a Digital Twin?

A Digital Twin is a virtual replica of a physical system, object, or process.

It dynamically responds to changes in its physical counterpart, enabling future state predictions and optimization without real-world interference.

As a key tool in Industry 4.0, Digital Twin supports production management through advanced computer simulation.

It enables 3D modeling of complex production and service systems and simulating multiple scenarios for process optimization.

contact form

Let’s discuss how Digital Twin can benefit your business!

Arkadiusz Wzorek

newsletter

01

01